A rotary compressor is a type of air compressor that creates compressed air using two rotating screws, commonly referred to as rotors. In comparison to other compressor types, rotary screw air compressors are cleaner, quieter, and more effective. They are also unbelievably dependable, even under continual use. Due to these reasons, rotary compressors are the go-to device for various business and industrial applications all over the world. Read More…

At KAPA Compressor USA, we pride ourselves on being a leading provider of air compressors and comprehensive solutions tailored to meet the diverse needs of our customers across various industries. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the compressed air industry. Our primary focus is on delivering a wide range of...

We offer a product calculator on our website to assist you in finding the exact compressor that will best suit your needs. Our 12 volt air compressor cannot be topped by the competition! We were established over 15 years ago and we want to put those years of experience to work for you! Visit our website today or get in touch with our customer service department to find out more about what we can...

We have been offering exceptional 12 volt air compressors since our inception in 1915. It is our goal that we are able to provide our clients with nothing but the best products available in the current market! Our technicians are well-trained to provide excellent customer service at all times to keep you coming back to us for all of your air compressor needs. Visit us on the web today!

At Hitachi Global Air Power US, LLC, we specialize in providing advanced air compressor solutions designed to meet the diverse needs of industries worldwide. With a legacy of engineering excellence and a commitment to innovation, we have established ourselves as a leading manufacturer and supplier in the compressed air industry. Our product portfolio encompasses a comprehensive range of air...

More Rotary Compressor

Operation of a Rotary Screw Feeder

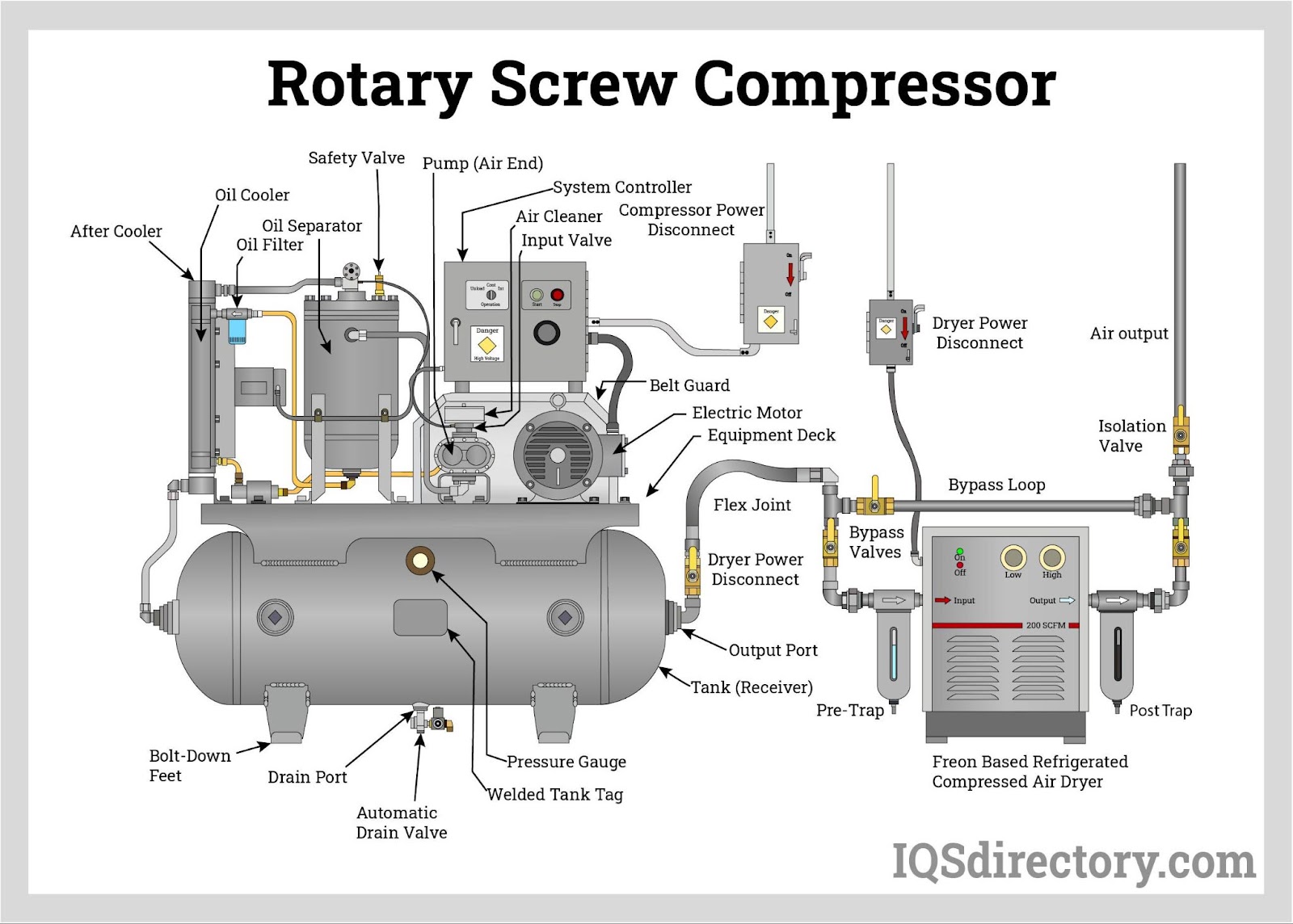

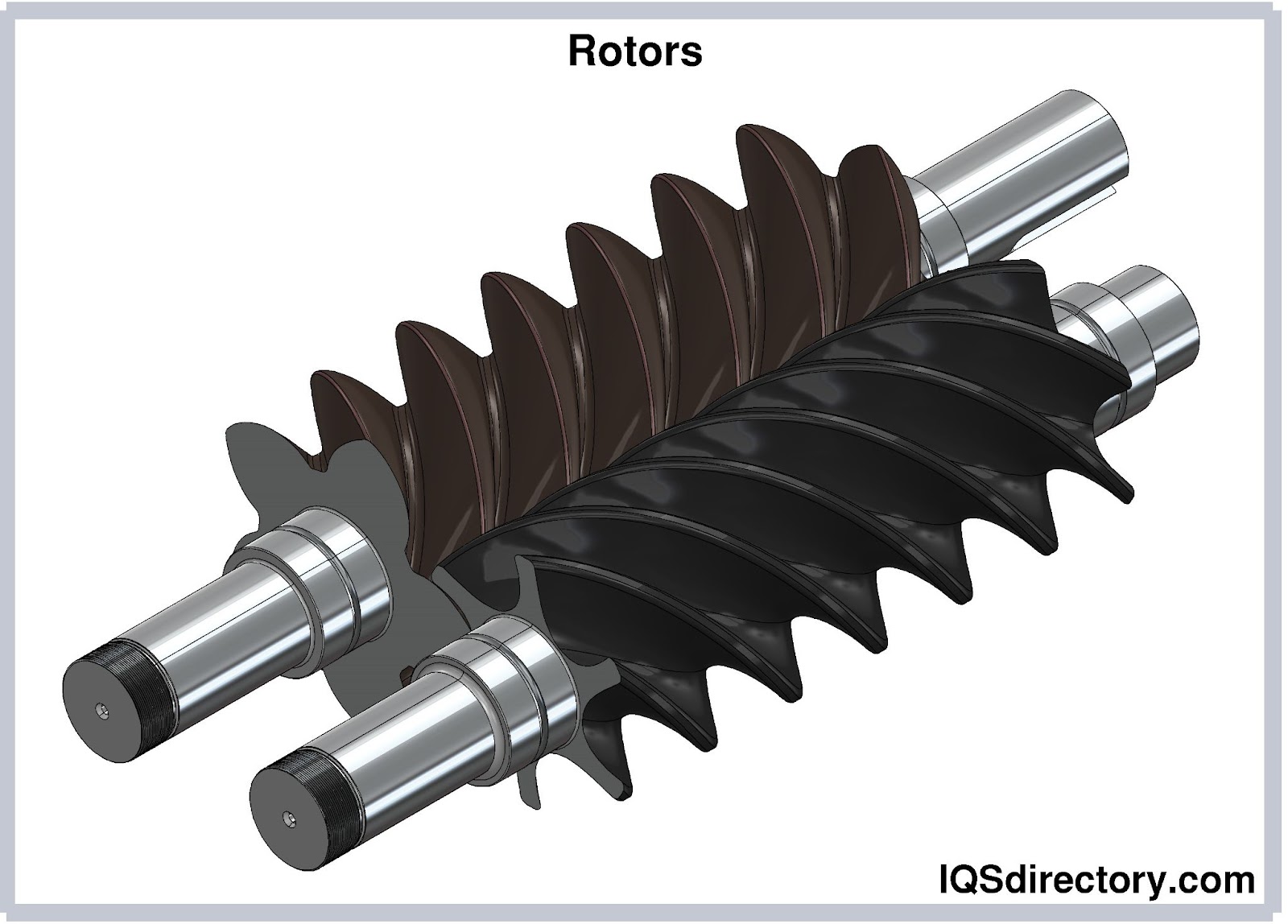

How do these compressors operate to produce compressed air? The innovative rotary screw technique that lends them their name has the solution to that query. Positive displacement describes the way rotary screw air compressors work. It is both straightforward and brilliant. They use two meshing helical screws, or "rotors," to compress the air. Timing gears ensure that the male and female rotors of a dry-running rotary screw compressor remain precisely aligned. Lubricating oil is used to fill the space between rotors in the case of oil-flooded rotary screw air compressors This creates a hydraulic seal and permits the transfer of mechanical energy.

Step-by-Step Operation of Rotary Screw Compressors

- Gas is drawn into the compression chamber by a valve when it is opened. The two screw rotors that are housed in the chamber rotate rapidly when the machine is turned on.

- Air is moved down the chamber as a result of the impellers' rotational action, which isolates and traps the air in the spaces between the rotors.

- The chamber is moved away from the opening valve.

- Volume decreases as pressure increases.

- Air is condensed due to the building pressure.

- The increasing air pressure triggers the compressor’s discharge valve to open, allowing the pressurized air to enter a receiver or other holding tank.

- After the air is compressed, it can be transferred and utilized for purposes ranging from drying to contamination removal.

Why Rotary Screw Compressors?

- Rotary screw compressors are energy-efficient by virtue of their compression mechanism. They are a great investment because energy prices make up the majority of the expenditures associated with compressing air.

- Additionally, rotary screw compressors are made specifically for long periods of dependable use. They are, therefore, a fantastic option for tasks that demand constant compressor operation.

- Additionally, rotary screw air compressors are incredibly adaptable and don't need a lot of maintenance. They are also comparatively silent. Therefore, it is possible to place these compressors close to the location of usage required without breaking noise regulations. For workshops or other small companies with constrained space, this is crucial.

- There is one more reason why rotary screw compressors are now prevalent in almost all sectors of the economy that use compressed air. Some rotary screw compressors have direct drives, some have gear drives, and others feature belt drives. Likewise, there are oil-flooded and dry-running compressors. In other words, there is a rotary screw air compressor for any need.

Different Rotary Screw Compressor Drives and Their Benefits

hree different forms of drive systems have been created to power rotary screw air compressors. Each has particular benefits.

- Belt-drive: As the name suggests, these compressors use a belt, which is connected to the motor, to run the air pump, and pulley system to generate air pressure and transfer power. This type of rotary screw compressor is reliable and simple to install and maintain. It also requires the least amount of upfront expenditure. It is an excellent option for any small businesses because of this combination of low price and low maintenance.

- Gear-drive: With this system, there are no belts or pulleys. An interconnected series of gears and chains form a gear train to generate the compressed air. This compressor is quieter thanks to its gear drive. It is more energy-efficient but typically comes with a higher initial investment cost. Consequently, this compressor must be used frequently to eventually pay off the increased price.

- Direct-drive: With a direct-drive system, the motor is directly connected to the air pump and doesn't require pulleys (or belts or gears) to help generate and transfer power. This version of rotary screw air compressors employs the most advanced technology, typically at more advanced prices. Direct-drive compressors provide unmatched performance and efficiency. These compressors can quickly recoup their higher initial investment cost due to their lower energy consumption and then continue to accrue savings after that. These compressors also have the lowest noise level of the three. Direct-drive rotary screw air compressors come in a variety of models for different applications

Rotary Compressor Applications

- The uses for rotary screw compressors are essentially limitless due to their numerous advantages, varieties, and sizes. However, there are some applications that are particularly well suited for them including commercial and industrial applications requiring large volumes of high pressure. The food and beverage industry, for example, utilizes rotary compressors for tasks ranging from cutting and preparing products to cleaning packages and workspaces.

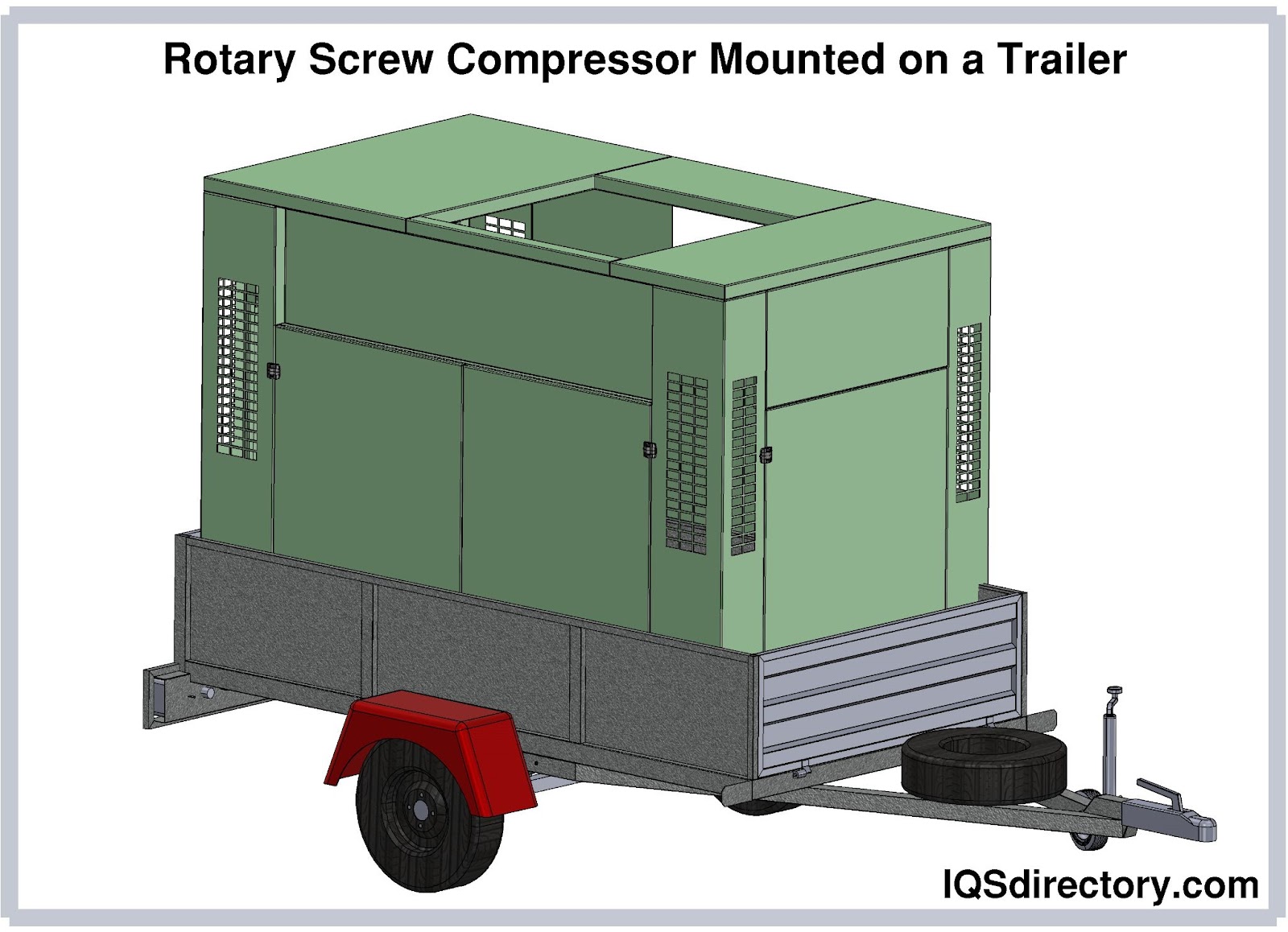

- Mobile versions of smaller rotary screw air compressors are common. They work perfectly for remote mining operations or construction sites. These are a few applications where the resilience and ease of installation show a clear advantage for rotary screw air compressors.

- As was already mentioned, users can choose between an oil-injected and an oil-free compressor. There are numerous applications where the caliber of compressed air is crucial. A few examples include the pharmaceutical industry, medical research, the food and beverage industry, or semiconductor production. The only option here should be an oil-free screw compressor.

- However, with an oil-injected compressor, the importance of air quality should be a secondary consideration such as when one simply needs to power pneumatic tools. Gas refrigeration and hydrocarbon processing are two further uses for oil-injected rotary screw air compressors.

Choosing the Correct Rotary Compressor Manufacturer

To make sure you have the most constructive outcome when purchasing Rotary Compressors from a Rotary Compressor Manufacturer, it is important to compare at least 4 or 5 Manufacturers using our list of Rotary Compressor suppliers. Each Rotary Compressor Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Rotary Compressor business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Rotary Compressor businesses with the same quote.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services