Environments such as medical offices, food processing plants, tattoo shops, clean room environments, research laboratories, public buildings and critical manufacturing lines require air that is 100% clean of microscopic oil particles that can contaminate both the equipment and the product. If the air output of oilless air compressors contains any oil in the air, no matter how small the amount, it is unacceptable for these environments. Read More…

At KAPA Compressor USA, we pride ourselves on being a leading provider of air compressors and comprehensive solutions tailored to meet the diverse needs of our customers across various industries. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the compressed air industry. Our primary focus is on delivering a wide range of...

We offer a product calculator on our website to assist you in finding the exact compressor that will best suit your needs. Our 12 volt air compressor cannot be topped by the competition! We were established over 15 years ago and we want to put those years of experience to work for you! Visit our website today or get in touch with our customer service department to find out more about what we can...

We have been offering exceptional 12 volt air compressors since our inception in 1915. It is our goal that we are able to provide our clients with nothing but the best products available in the current market! Our technicians are well-trained to provide excellent customer service at all times to keep you coming back to us for all of your air compressor needs. Visit us on the web today!

At Hitachi Global Air Power US, LLC, we specialize in providing advanced air compressor solutions designed to meet the diverse needs of industries worldwide. With a legacy of engineering excellence and a commitment to innovation, we have established ourselves as a leading manufacturer and supplier in the compressed air industry. Our product portfolio encompasses a comprehensive range of air...

More Oilless Air Compressor

Generally more reliable, oilless air compressors can be used in industries requiring continuous pressurized gas such as metal processing, electronics, semi-conductor, food processing, chemical, industrial, medical, automotive and aerospace. Other types of air compressors include rotary, screw and mini air compressors, all of which may be made oil free. Oilless air compressor manufacturers offer products that may cost more at purchase, but become more economical over time due to higher-energy efficiency as well as increased profit potential.

There are two types of air compressors that are oil free: centrifugal compressors and rotary screw air compressors. While centrifugal compressors are always oil free, rotary screw compressor manufacturers are manufacturing more oil free rotary screw compressors for precision applications in recent years than lubricated rotary screw compressors.

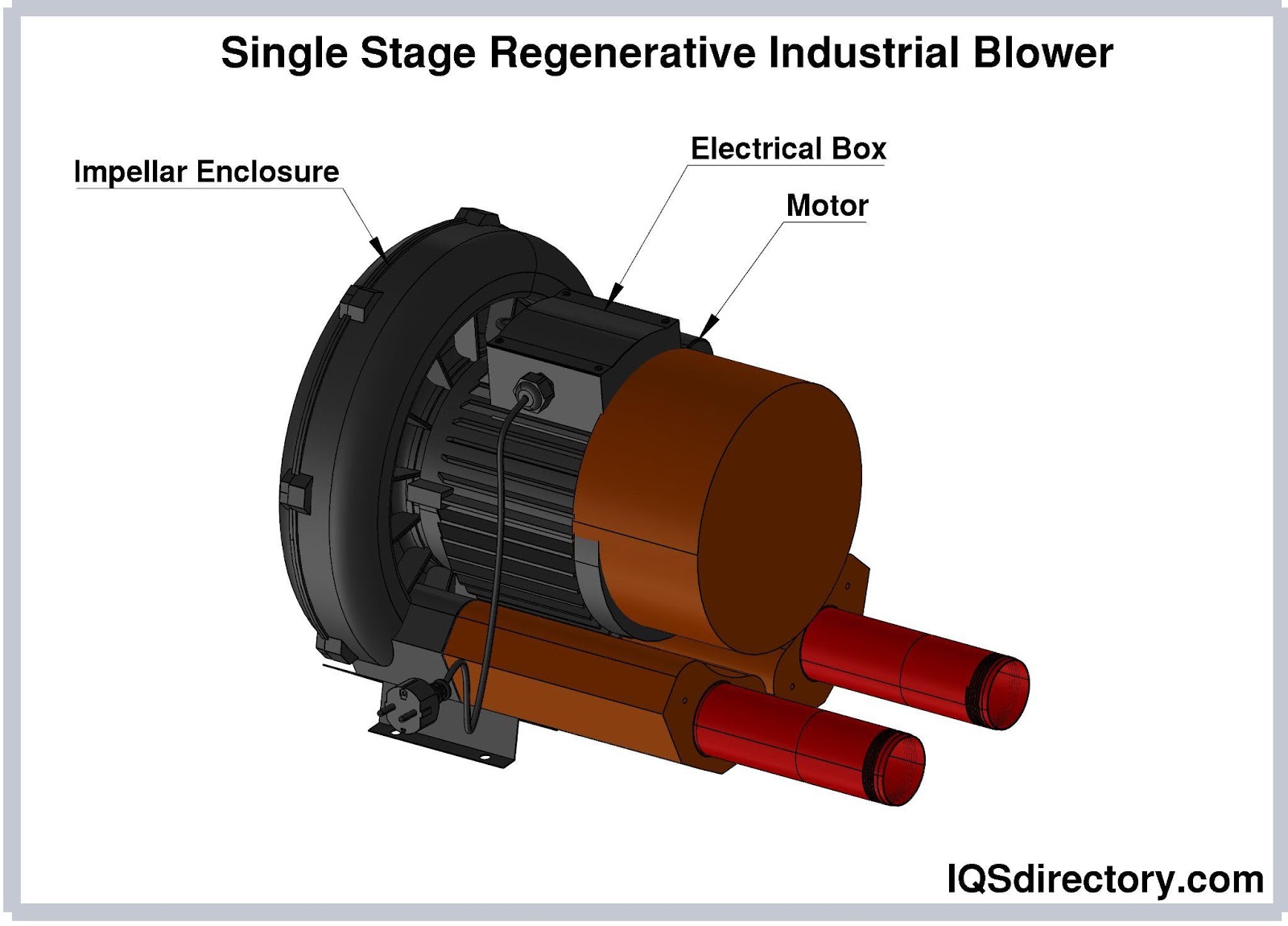

Centrifugal compressors are turbo machines that act as fans, blowers, pumps and compressors to provide high pressure airflow for a number of large industrial applications. A rotary impeller draws air in through the compressor’s inlet, imparting high velocity to the air with rapid rotary motion; the kinetic energy of the air is converted to pressure as the air or gas is channeled into a diffusing chamber and out through a discharge nozzle. Due to the centrifugal compressor’s use of a rotary impeller, they contain no lubricants, which might come in contact with the air stream.

Oil-free rotary screw compressors use two helical screws fitted into one another, rotating quickly in opposite directions. The meshing and rotation of the two helical rotors produces a series of volume-reducing cavities; gas is drawn in through an inlet port in the casing, captured in these cavities, compressed and then discharged through another port in the casing. The design is oil-free because the air is compressed entirely through the action of the screws, without the assistance of an oil seal.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services