When the crankshaft pushes the piston up, the air is pushed into a tank with a one-way check valve that does not permit it back into the cylinder. As more air enters the tank, the pressure increases. When the piston is pulled down, new air enters and the process begins again. Read More…

At KAPA Compressor USA, we pride ourselves on being a leading provider of air compressors and comprehensive solutions tailored to meet the diverse needs of our customers across various industries. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the compressed air industry. Our primary focus is on delivering a wide range of...

We offer a product calculator on our website to assist you in finding the exact compressor that will best suit your needs. Our 12 volt air compressor cannot be topped by the competition! We were established over 15 years ago and we want to put those years of experience to work for you! Visit our website today or get in touch with our customer service department to find out more about what we can...

We have been offering exceptional 12 volt air compressors since our inception in 1915. It is our goal that we are able to provide our clients with nothing but the best products available in the current market! Our technicians are well-trained to provide excellent customer service at all times to keep you coming back to us for all of your air compressor needs. Visit us on the web today!

At Hitachi Global Air Power US, LLC, we specialize in providing advanced air compressor solutions designed to meet the diverse needs of industries worldwide. With a legacy of engineering excellence and a commitment to innovation, we have established ourselves as a leading manufacturer and supplier in the compressed air industry. Our product portfolio encompasses a comprehensive range of air...

More Reciprocating Compressor

The reciprocating compressors are the most common of all the air compressor designs, and are utilized in oil refineries, gas pipelines, chemical plants, natural gas processing plants, and refrigeration plants. A compressor is a component of a vapor compression refrigeration system, which is the most common method for air conditioning of public buildings and residences.

Reciprocating compressors are a specific model of positive displacement compressors, which generally use pistons within cylinders to control the flow of air in and out of the mechanism. Rather then filling and collapsing with air, another type of compressor, the rotary screw compressor, uses two precisely aligned helical screws to collect air through a sealant and release it again by way of the rotating screws.

Reciprocating compressors differ from screw compressors by the method of compression they employ, but are able to be utilized in similar applications. Rotary screw compressors involve lubrication more often then reciprocating compressors, but both can be oil free. The benefits of oilless air compressors are guaranteed clean air, with no oil carryover, cost-efficiency and earth friendliness.

Air compressors are typically made of cast iron, aluminum, stainless steel or a combination of these materials. However, when a light weight compressor is desired, the air compressor may be built from plastic instead. The pistons or other minor components may be made of plastic in small air compressors as well. There are different varieties of reciprocating compressors that are styled depending on the applications.

In a single stage reciprocating compressor, all of the compression takes place in a single cylinder. Multi-stage compressors will compress the air to intermediate pressures in two or more steps before the final desired pressure is reached. Some reciprocating compressors have been known to operate up to six cylinders at once. This allows for higher pressures to be reached, but can limit the cubic feet per minute, or CFM.

These large examples of compressors are powerful and impressive, but the small and portable reciprocating compressors are used as often if not more so, and are therefore just as important. Portable compressors are utilized in industrial companies as well, but by powering small pneumatic tools, such as sand blasters, drills, nail guns and staplers.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

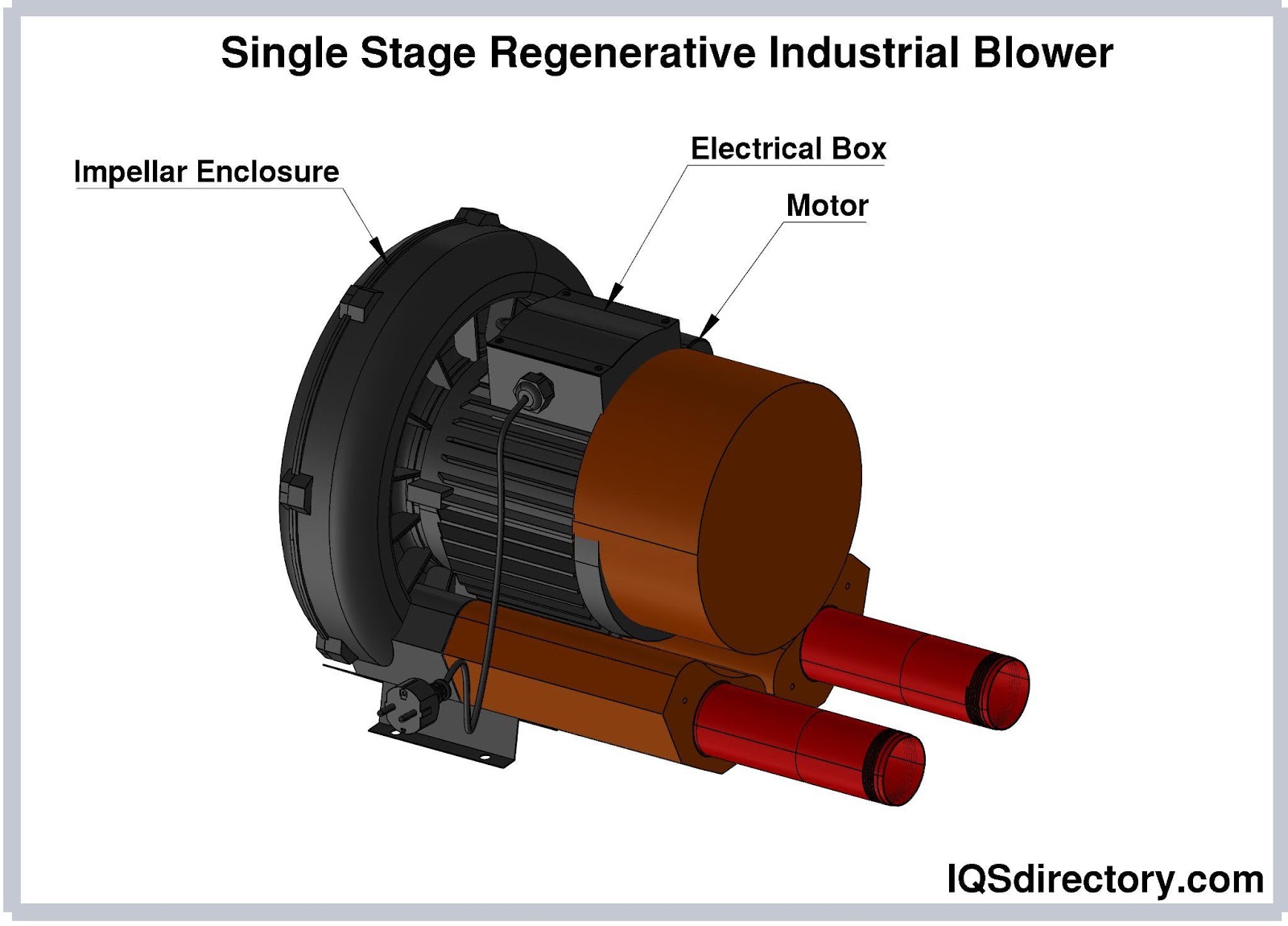

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services