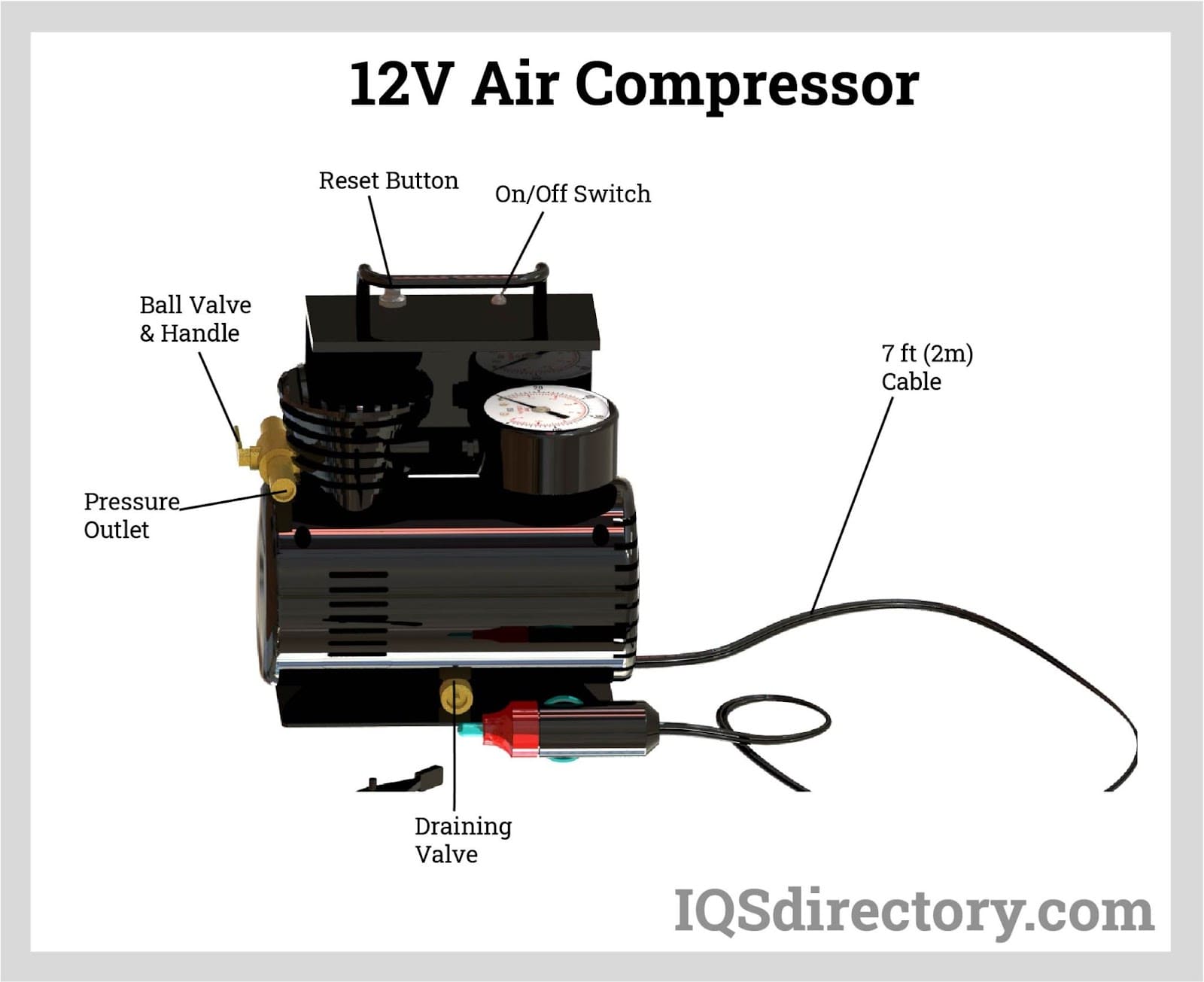

12V air compressors transform air into kinetic energy by compressing it and storing it for later use. While large companies typically use air compressors with higher voltages for their needs, a 12V air compressor is generally enough for smaller businesses and individuals who don’t require it for large, industrial applications. In fact, purchasing a larger one would be impractical under these circumstances since larger ones require engines to function and are more expensive. Read More…

Our 12 volt air compressors cannot be topped! We have been in business since 1996 and ever since then we have been providing goods and services that are top of the line. Our products serve the U.S. Government and are made in the USA. We will work with you closely to come up with the exact product that will fit your needs! Visit our website or get in touch with our customer service department...

Kaishan Compressor USA is a renowned leader in the field of air compressors, dedicated to delivering cutting-edge compressed air solutions to meet the diverse needs of industries across the United States. With a strong commitment to innovation, quality, and customer satisfaction, we have established ourselves as a trusted partner for businesses seeking reliable and efficient compressed air...

PneuTech USA is a renowned leader in the field of air compressors, dedicated to delivering cutting-edge compressed air solutions to meet the diverse needs of industries across the United States. With a strong commitment to innovation, quality, and customer satisfaction, we have established ourselves as a trusted partner for businesses seeking reliable and efficient compressed air systems. Our...

Metro Air Compressor is a full-line distributor of compressed air products, such as rotary screw compressors, centrifugal compressors, piston compressors, vacuum pumps, dryers, filtration, and water cooling systems. Our company is proud to have been providing exceptional air compressors in Michigan since 1975. We also provide repair, maintenance, installation, and rental services. Contact the...

More 12 Volt Air Compressor

Applications for 12-Volt Air Compressors

- Due to their tiny size and low maintenance needs, the 12V air compressor offers households great convenience. This compressor is lightweight and portable, making it ideal for easy storage or for travel during those unfortunate times you may immediately need it. Whether used for personal or professional purposes, these air compressors have found great usage.

- A 12V compressor operates under one of two working principles- dynamic displacement or positive displacement. The positive displacement tool type is identified by the compressor that fills and empties an air chamber during operation. The dynamic compressor, on the other hand, uses a spinning mechanism to either accelerate or decelerate the air; by increasing the speed or velocity of air, it is possible to raise the air's pressure.

- Typically, 12V compressors have required an electrical outlet source through a home or business in order to operate. More recently, however, various manufacturers have created rechargeable compressors that can be plugged into a cigarette lighter socket in a car to meet one’s off-road needs. They are handy and incredibly accessible for folks who are often on the run.

- 12V air compressors are readily accessible through most megastores or home improvement stores across the world. To confirm a device is expertly crafted and of high quality while purchasing a 12V compressor, look for the ASME seal on the product.

Benefits of 12V Air Compressors

- People may want a portable air compressor for a variety of reasons. While there will be times when a nearby conventional power source (like the grid outlets in the house or garage) is available, many users will choose to use, or be forced to use, their air compressor in locations that are far from conventional power sources. If one enjoys camping, one might need to inflate their tents, air mattresses, or bicycle tires; a boater may need to raise the pressure in an inflatable boat.

- For those with a swimming pool, one might wish to inflate a variety of pool accessories with a 12V air compressor instead of making multiple trips to and from the house.

- Additionally, many 12V compressors function as part of a system including power connectors so that the user may use it to power his/her camping gear and other devices like portable refrigerators, spotlights, and auto vacuum cleaners.

- Typically, 12V power sources nowadays are portable batteries that can be carried around together with the compressor in one’s vehicle to a campsite or recreational area without any hustle.

- These innovative little devices may also include a work light so that the user can jump-start his car or pump a tire with adequate lighting to complete the task. Additionally, some devices feature safety illumination that other drivers can such as flashing warning lights.

Choosing the Right 12 Volt Air Compressor Supplier

To make sure you have the most beneficial outcome when purchasing 12 Volt Air Compressors from a 12 Volt Air Compressor Supplier, it is important to compare at least 4 Companies using our list of 12 Volt Air Compressor manufacturers. Each 12 Volt Air Compressor Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each 12 Volt Air Compressor company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple 12 Volt Air Compressor businesses with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services