Air compressors are an essential component in modern industry, serving a wide range of applications across various sectors. They are devices that convert power into potential energy stored in compressed air. This compressed air can be used for powering tools and equipment, as well as for pneumatic control systems. The history of air compressors dates back to ancient times when people used simple hand-operated bellows to generate compressed air. Read More…

At KAPA Compressor USA, we pride ourselves on being a leading provider of air compressors and comprehensive solutions tailored to meet the diverse needs of our customers across various industries. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the compressed air industry. Our primary focus is on delivering a wide range of...

We offer a product calculator on our website to assist you in finding the exact compressor that will best suit your needs. Our 12 volt air compressor cannot be topped by the competition! We were established over 15 years ago and we want to put those years of experience to work for you! Visit our website today or get in touch with our customer service department to find out more about what we can...

We have been offering exceptional 12 volt air compressors since our inception in 1915. It is our goal that we are able to provide our clients with nothing but the best products available in the current market! Our technicians are well-trained to provide excellent customer service at all times to keep you coming back to us for all of your air compressor needs. Visit us on the web today!

At Hitachi Global Air Power US, LLC, we specialize in providing advanced air compressor solutions designed to meet the diverse needs of industries worldwide. With a legacy of engineering excellence and a commitment to innovation, we have established ourselves as a leading manufacturer and supplier in the compressed air industry. Our product portfolio encompasses a comprehensive range of air...

More Air Compressor Manufacturers

The first compressed air-powered machine was invented by French scientist Denis Papin in 1687, which used compressed air to power a piston engine. The modern air compressor as we know it today was developed in the 19th century and has undergone numerous advancements in technology since then.

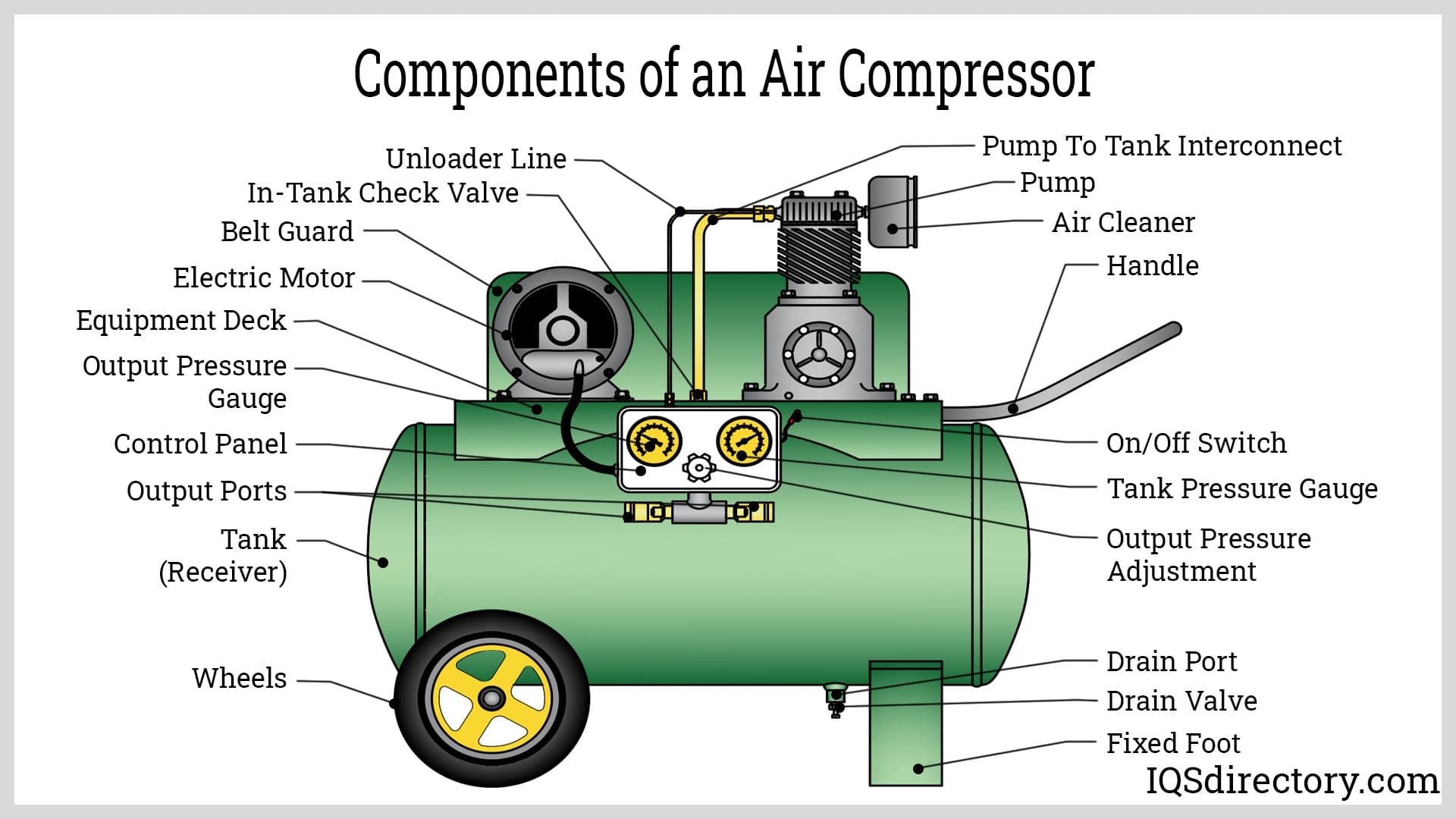

Components of Air Compressors

Air compressors work on the basic principle of compressing air to increase its pressure and store it in a tank for later use. The compressor’s components include a motor, a pump, an air tank, and various valves and gauges. These components are explained in further detail below.

Motor: The motor is the power source of the air compressor, typically an electric or gasoline engine. It provides the energy needed to drive the compressor’s pump.

Pump: The pump is the heart of the air compressor, responsible for compressing air and increasing its pressure. There are several types of air compressor pumps, including reciprocating, rotary screw, and centrifugal pumps.

Air tank: The air tank is a vessel designed to store compressed air until it is needed. The size of the tank depends on the application and the required volume of compressed air. The air tank is equipped with safety valves to prevent over-pressurization.

Gauges: Gauges are instruments that measure pressure, temperature, and other parameters. An air compressor typically has two gauges – one to measure the air pressure inside the tank and the other to measure the pressure at the tool or equipment outlet.

Valves: Valves are used to control the flow of compressed air in an air compressor. The most common types of valves used in air compressors include the inlet valve, discharge valve, check valve, and safety valve. The inlet valve controls the air intake, while the discharge valve controls the air release. The check valve prevents backflow of compressed air, and the safety valve is designed to release excess pressure in the air tank if it exceeds a safe limit.

Each of these components plays a critical role in the functioning of an air compressor. The motor provides the energy, the pump compresses air, the air tank stores compressed air, the gauges monitor pressure, and the valves control the flow of compressed air. Together, they form a system that converts power into potential energy stored in compressed air, making it a valuable tool for various applications.

Types of Air Compressors

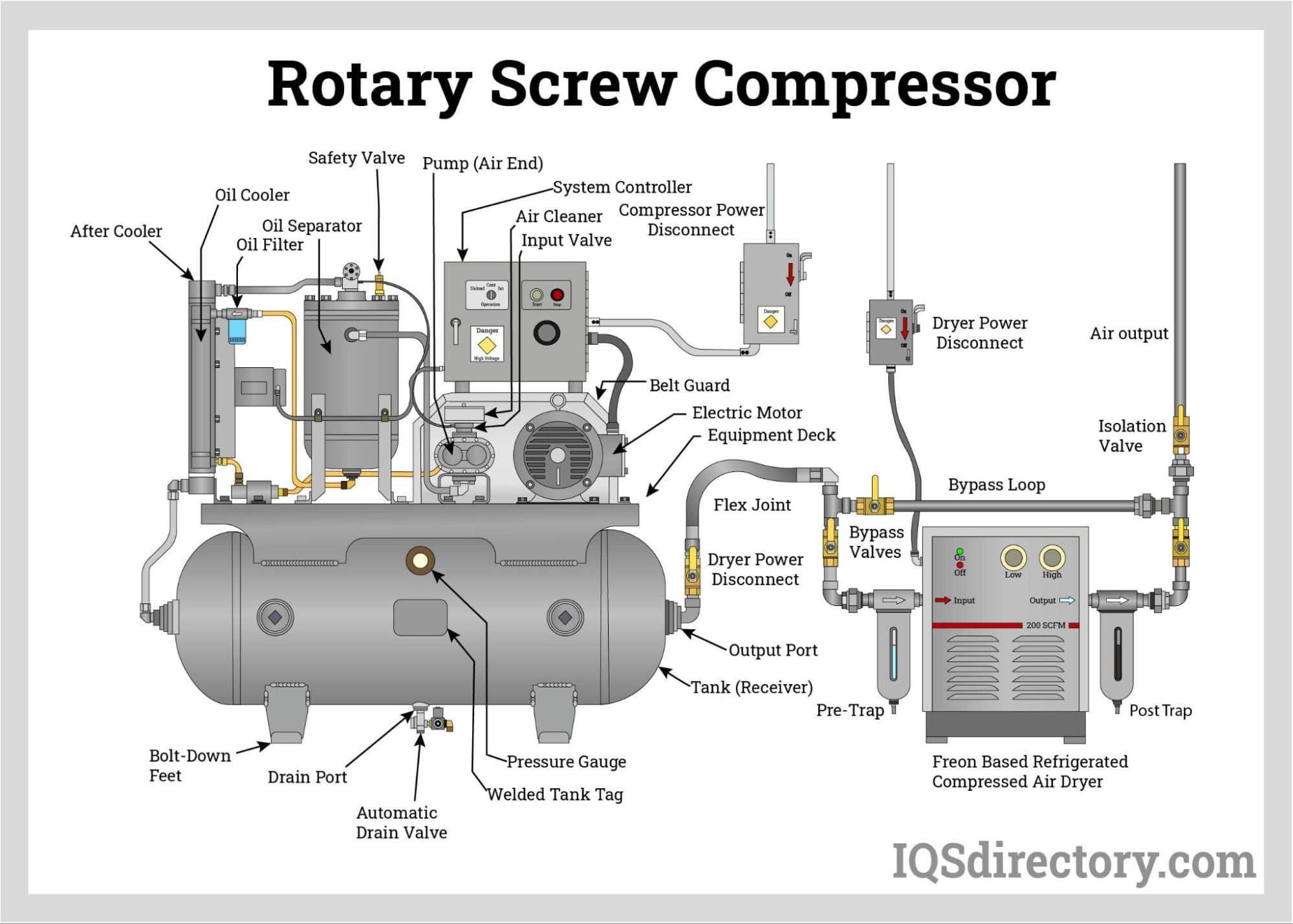

There are several types of air compressors, each with its own unique design and operation. Reciprocating compressors, also known as piston compressors, use a piston and cylinder arrangement to compress air. They are widely used and suitable for both small and large-scale applications. Rotary screw compressors, on the other hand, employ two interlocking helical screws to compress air. These compressors are known for their high efficiency, continuous operation, and lower maintenance requirements. Centrifugal compressors, meanwhile, work by accelerating air using a rotating impeller and converting the kinetic energy into pressure. They are commonly used in large industrial applications where high volumes of compressed air are required. Finally, axial compressors are often found in aircraft engines and gas turbines, where air is compressed in a series of rotating and stationary blades. They are capable of handling large volumes of air but operate at high speeds and pressures. Each type of air compressor has its advantages and is suited for specific applications based on factors such as required air volume, pressure, and operational characteristics.

Limitations of Air Compressors

While air compressors offer numerous benefits, they also have certain limitations and drawbacks to consider. One major limitation is their energy consumption. Compressing air requires a significant amount of power, and this energy consumption can contribute to higher operating costs. Additionally, air compressors require regular maintenance to ensure optimal performance and prevent issues such as leaks, wear and tear, and contamination. Failure to maintain the compressor properly can lead to decreased efficiency and increased downtime. Another consideration is the noise pollution generated by air compressors. They can produce high levels of noise during operation, which can be disruptive in certain environments and may require additional measures to mitigate the noise. It is important to be aware of these limitations and address them accordingly, such as investing in energy-efficient models, following recommended maintenance schedules, and implementing noise reduction measures when necessary.

Benefits of Air Compressors

Despite their limitations, air compressors offer numerous benefits. They increase efficiency and productivity by powering tools and equipment, and they are versatile in their applications. Air compressors can also save costs in the long run by reducing the need for manual labor and increasing the lifespan of tools and equipment. Let’s examine these benefits.

Increased efficiency and productivity: Air compressors can power a wide range of tools and equipment, making it possible to complete tasks more efficiently and quickly than with manual labor. They also enable continuous operation of pneumatic systems, increasing overall productivity.

Cost savings: Air compressors can save costs in the long run by reducing the need for manual labor and increasing the lifespan of tools and equipment. They can also help reduce waste by providing precise control over the amount of compressed air used.

Versatility in applications: Air compressors can be used for a wide range of applications, including powering tools, inflating tires, sandblasting, and more. This versatility makes them an excellent investment for businesses and individuals.

Additional benefits: In addition to the previously mentioned benefits, air compressors offer several other advantages worth noting. To start, they contribute to a safer work environment by eliminating the need for hazardous manual labor and reducing the risk of strain injuries and accidents. Air compressors can also provide clean and oil-free compressed air, making them suitable for applications where contamination can affect product quality or damage sensitive equipment. Additionally, portable air compressors are designed for easy storage and transport, offering flexibility and convenience in different work environments. Many air compressors also have the advantage of instant start-up and shutdown, allowing for quick activation or deactivation and immediate access to compressed air as needed. Moreover, air compressors provide versatile pressure adjustment capabilities, enabling precise control and optimal performance when operating pneumatic tools or equipment with varying pressure requirements. These additional benefits make air compressors even more valuable and versatile in a wide range of industries and applications.

Applications of Air Compressors

Again ,the many benefits provided by air compressors leads to their use in numerous applications, including industrial uses such as manufacturing, construction, and mining, as well as in-home and DIY applications. They are also used in the automotive and transportation industry, and with medical and dental applications. These applications are highlighted below.

Industrial uses: Air compressors are widely used in manufacturing, construction, and mining industries to power tools, operate pneumatic systems, and control equipment. They are also used in the oil and gas industry for drilling and powering hydraulic fracturing operations.

Home and DIY applications: Air compressors can be used for various home and DIY projects, such as inflating tires, cleaning air filters, painting, and powering air tools.

Automotive and transportation applications: Air compressors are used in automotive and transportation industries to power tools, inflate tires, and operate pneumatic systems.

Medical and dental applications: Air compressors are used in medical and dental settings to power dental drills, operate breathing equipment, and provide compressed air for medical instruments.

The Future of Air Compressors

The potential future of air compressors holds exciting possibilities for advancements in technology that focus on enhancing efficiency, reducing environmental impact, and expanding capabilities. One area of possible development is the pursuit of enhanced efficiency through advanced control systems and variable speed drives. These innovations could optimize energy consumption by adjusting compressor output to match demand, resulting in improved efficiency and reduced power consumption. Another significant direction is the potential integration of renewable energy sources. By incorporating solar or wind power, air compressors could become more sustainable, relying less on conventional energy sources and reducing their carbon footprint.

Furthermore, the rise of the Internet of Things (IoT) is expected to play a significant role in the future of air compressors. Smart and connected technology could enable air compressors to be part of a network, allowing for remote monitoring, data analysis, and predictive maintenance. Real-time insights and proactive maintenance could optimize performance, minimize downtime, and improve overall efficiency.

Advancements in materials and designs are also anticipated. Lightweight components, improved heat dissipation mechanisms, and innovative construction techniques could enhance durability, reduce weight, and improve overall performance. This could lead to more compact and portable air compressors without compromising on power.

The future of air compressors may also involve ongoing efforts to reduce noise and vibration. Research and development in noise reduction and vibration control technologies would result in quieter operation, enabling their use in noise-sensitive environments and enhancing the user experience.

Additionally, the expanding applications of air compressors are a significant area of likely growth. Emerging industries such as alternative energy, aerospace, and medical sectors may require customized air compressor solutions to meet their specific needs. As new technologies emerge and industries evolve, air compressors have the potential to find applications in previously untapped areas.

The future of air compressors should be influenced by factors such as ongoing research and innovation, energy efficiency trends, environmental regulations, and technological advancements. As these developments continue to unfold, air compressors are poised to become more efficient, eco-friendly, and adaptable to the evolving needs of various industries.

Choosing the Correct Air Compressor Supplier

To ensure you have the most productive outcome when purchasing an air compressor from an air compressor supplier, it is important to compare several companies using our directory of air compressor suppliers. Each air compressor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each air compressor business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple air compressor companies with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services